ball end mills are used

Ball End Mills have a hemispherical tip used to machine rounded details such as the metal bearing grooves found in machines. Ball mills crush material into various sizes and extract resources from mined materials.

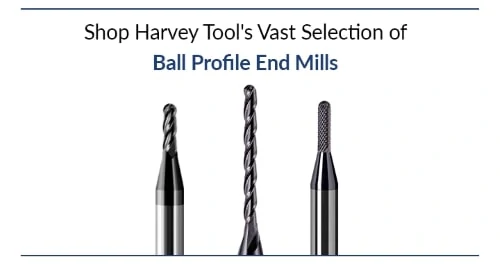

End Mills The Essential Beginners Guide

Ad High-Precision Burrs Held to End Mill Tolerances.

. Ball mills are a fundamental part of the manufacturing industry in the USA as well as around the world. High Flute Count Allows for Increased Feeds Which Reduces Cycle Times. Small diameter ball nose end mills are used for projects with intricate detail while larger bits are used.

Milling of free form surfaces using ball-end milling is the main operation in this application known as sculptured surface milling SSM Choi and Jerard 1999. They can be used as roughing tools where a design incorporating a large core neutral cutting angles and slow helix coupled with the full radius and used with HSM machining techniques can yield extremely long life in the hardest of materials. Ad Free Shipping Available.

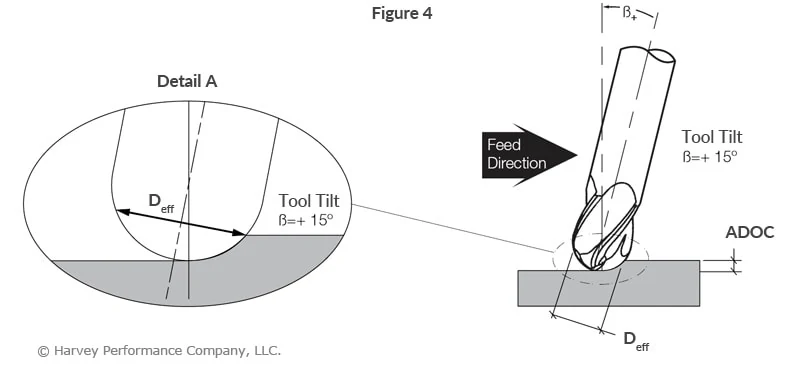

Ball Nose Milling Without a Tilt Angle. Ball end mills also known as ball nose end mills are used for milling contoured surfaces slotting and pocketing. Double Cut Style Flute Pattern.

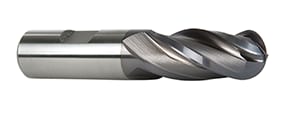

Ball nose end mill. They can be used used for milling a large corner radius grooving with a full radius and contour or profile milling. Stub Length Ball End Mill.

End mills are used on CNC or manual milling machines. In all ore dressing and milling Operations including flotation cyanidation gravity concentration and amalgamation the Working Principle is to crush and grind often with rob mill or ball mill the ore in order to liberate the minerals. Also called Ball Nose End Mills they are used extensively in manufacturing tools dies and machining complex three dimensional contours with.

With a radius at the bottom which makes for a greater surface finish produces a rounded pass ideal for 3D contour work shallow slotting pocketing and. This enables a cnc machine to machine complex flowing shapes to. They can be general purpose or high perfomance geometries.

MrRon from South Mississippi. I have never used ball end end mills before. Ball nose mills have a radius at the bottom which makes for a nicer surface finish in your workpiece meaning less work for you as the piece wont need to be finished any further.

Also known as ball-nose end mills they are rotated against a workpiece to make round-bottomed slots and pockets or mill complex shapes without sharp corners. The smaller diameters can be used for engraving. Ball end mills are 2 3 or 4 flutes end mills and available in stub length standard length long length extra-long length and extra-long reach models.

Ball end mills are available in dia. Obviously they can cut a cove with a radius the same as the bit but other than that what else can a ball end end mill be used for. Made in the USA.

Ad Browse discover thousands of brands. Ball nose end mills are ideal for machining 3-dimensional contour shapes typically found in the mold and die industry the manufacturing of turbine blades and fulfilling general part radius requirements. Also called Ball Nose End Mills they are used extensively in manufacturing tools dies and machining complex three dimensional contours with a smooth finish.

Ball-end milling is also known as copying milling because of the old practice of copy forms from jigs 40 years ago before the introduction of CNCs in milling machines. By incorporating various design elements ball nose end mills can be tailored to a wide range of applications. They are used for contour milling shallow slotting pocketing and contouring applications.

Due to their shape they are particularly suited to machining 3D part contours milling large corner radii and grooving with a full radius. Ball nose spiral end mills are used for smooth contouring and fine detail passes with a CNC router and often for complex shapes like 3D carvings. In the chemical and process industries grinding is an important step in preparing raw materials for subsequent.

And different coating finishes. Ball end mills are used for a variety of milling operations such as contouring profiling slotting and pocketing. Pebble mills are a type of ball mill and are also used to reduce the size of hard materials down to 1 micron or less.

A ball end mill is constructed of a round. There are a few ball end mill uses the big one being the ability to produce free form curves. Ball End Mills have a hemispherical tip used to machine rounded details such as the metal bearing grooves found in machines.

End mills in different shapes. Ball End Mills are very durable and come with an array of surface coatings tailored for. Here we talk about some common types of end mills.

Ball Nose End Mills. High-Speed Steel Ball End Mills with Two Milling Ends When one end wears out switch to the opposite end for two times the life of a standard high-speed steel end mill. Read customer reviews find best sellers.

Ball end mills also known as ball nose end mills are used for milling contoured surfaces slotting and pocketing. To properly employ a ball nose end mill with no tilt angle and gain the optimal tool life and part finish follow the 2-step process. A ball end mill is constructed of a round cutting edge and used in the machining.

They are available in a wide variety of standard sizes and lengths. The rounded ends produce smooth curves that would be impossible to achieve with flat end bits. Made of high-speed steel these end mills are for general purpose milling in most material such as aluminum brass bronze iron and steel.

Each end mill has flutes on its cutting head that carry chips away from the workpiece to prevent damage to the end mill or workpiece.

Basic End Mills Technical Information Msc Industrial Supply Co

Ball End Mill An Overview Sciencedirect Topics

End Mills Cad Cam Engineering Worldwide

End Mills The Essential Beginners Guide

End Mills The Essential Beginners Guide

What Are The Different Types Of End Mills A Person Can Purchase Quora

End Mills The Essential Beginners Guide

Ball Nose Milling Strategy Guide In The Loupe

Osg Taps End Mills Drills Indexable Composite Tooling Diamond Coating Die Products Osg Cutting Tools For Milling Applications

Types Of End Mills Difference Between End Mill And Drill Bit What Is End Milling Cnclathing

Basic End Mills Technical Information Msc Industrial Supply Co

Basic End Mills Technical Information Msc Industrial Supply Co

Skip To Content Robbjack Corporation Menu Solutions Spotlight Making The Switch To Aluminum For Lightweight High Performing Automotive Applications Only Robbjack S A1 303 Met This Machining Requirement Where Over 20 Other Toolmakers Failed See

End Mills The Essential Beginners Guide

Ball Nose Milling Strategy Guide In The Loupe